|

PLUMBING , DRAINAGE, FIRE SAFETY, FLUID HANDLING & MECHANICAL SUPPLIES

ALPINE STEEL offers expanding range of floor drains, roof drains, shower drains, floor Clean Outs and floor gullies as per designer’s requirements. Our range comprises standard and customized solutions with vertical and horizontal spigot connection.

FLOOR & ROOR DRAINS,

SHOWER DRAINS, FLOOR CLEAN OUTS

BACKWATER VALVE

|

Models

|

Nomenclature

|

Figures

|

|

AGSD301

|

Three piece Shower drain

6”x6” Square frame and round strainer and blind plate, for 3” and 4” pipe size, stainless steel 300 series, blind solid round plate and strainer.

|

|

|

AGSD302

|

Open strainer Shower drain

6” x 6” Square frame with round grating, No hub pipe connection, Open strainer, Cast Brass or Stainless steel 300 series.

|

|

|

AGFD303

|

Floor drain

Material Ni-Bronze, adjustable connection for 3” and 4” pipe size, secured strainer.

|

|

|

AGSD304

|

Three piece Shower drain

6”x6” Square frame, for 3” and 4” pipe size, stainless steel 300 series, blind solid Square plate and round strainer.

|

|

|

C911

|

Angle Drain W 450 grate

Cast Iron Body and Slope grate, for 6” Pipe size outlet the grate free area is 20 in2, and for 4” (9 in2). No hub outlet. This type of drain is used in elevator pits, pools and trenches where a side wall outlet is required. The angle rate is located in the wall to prevent blockage by debris.

|

|

|

C911-90deg

|

Angle Drain W 900 grate

Cast Iron Body and Slope grate, for 6” Pipe size outlet the grate free area is 20 in2, and for 4” (9 in2). No hub outlet. This type of drain is used in elevator pits, pools and trenches where a side wall outlet is required. The angle rate is located in the wall to prevent blockage by debris.

|

|

|

C916

|

Back Water Valve

Used for drain lines to safeguard lower areas from sewer backup.

Body Cast Iron, Bolted Cover sealed with gasket, offset inlet (hub) and outlet (spigot), flapper bronze cast swing assembly.

|

|

| C909 |

ROOF DRAIN

Cast Iron body with vertical bottom No-Hub 75 mm outlet, removable Cast Iron and Aluminum dome strainer and membrane flashing clamp

|

|

| C908 |

Floor Drain with integral P TRAP

Cast Iron body available in 3", 4" and 6" IPS

|

|

| PD1201 |

PARKING DRAIN

Cast Iron Body, Bucket, grating cover, available in 6" and 8" outlet, No Hub joint.

|

|

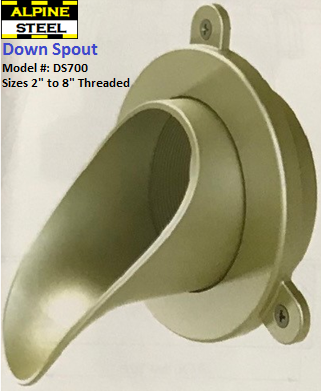

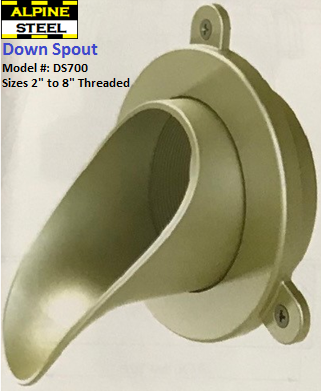

| DS700 |

ALPINE DOWN SPOUT NOZZLE

For rain water outlet size 2" TO 8” inch, Nickel Bronze Body with threaded outlet with wall flange.

|

|

Specifications:

|

PRODUCT STANDARDS:

FLOOR AND TRENCH DRAINS ASME A112.6.3-2001.

CLEANOUTS ASME A112.36.2M-1991.

ROOF DRAINS ASME A112.21.2M-1983.

|

MATERIALS

All materials adhere to the following standard codes.

A. Gray cast iron material according to BS EN 1561, [BS 1452-WITHDRAWN CODE].

B. Aluminum according to BS 1490 (LM6 grade).

C. Nickel Bronze according to BS 1400.

|

|

QUALITY ENFORCEMENT SEGMENT

To enforce quality control process, the following tests and inspections points are conducted periodically.

A. Chemical Test - Chemical analysis of the metal in the solid state is carried out to determine the exact percentage of all elements.

B. Mechanical Tests - Tensile testing of separate cast bars are assessed and compared to applicable standards.

C. Visual Inspection - All castings are inspected visually by our Quality Control Staff prior to dispatch.

D. Compression Test is conducted, to determine load bearing capacity of the top of the drain All results are based on item's applicable standard.

|

|